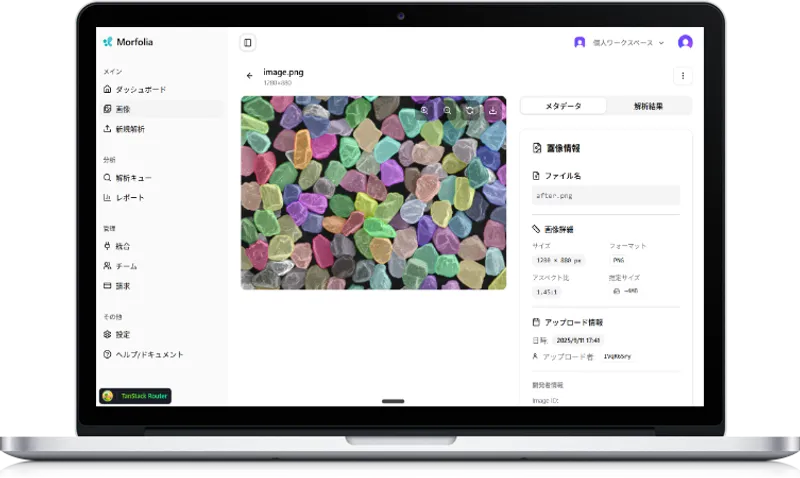

Morfolia is a service provided by Read Co., Ltd. to analyze the shape of particles and powders.

No high-end

PC

Use your

browser

Just

upload

形状解析を行うことで、粒子の形状を定量的に表現することができます。

粒子をクリックしてみてください。

1

Create Account

First, create your Morfolia account. Simply enter your email address and password to get started quickly and easily.

2

Upload Images

Upload microscopic images of particles or powders you want to analyze. Easy upload via drag & drop or file selection.

3

View Results

View AI analysis results of your uploaded images. Shape data is quantified and displayed in graphs and reports.

| Traditional Image Analysis | | |

|---|---|---|

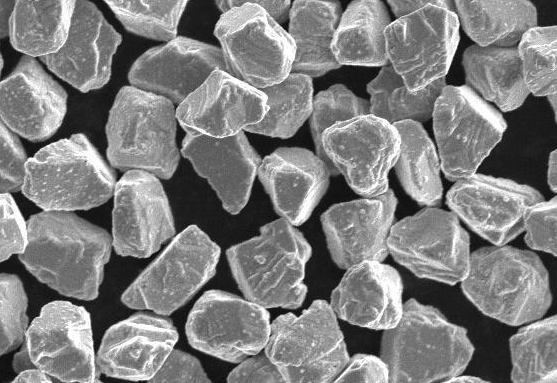

| Approach | Binarization + Watershed | Deep Learning Model |

| Overlapping Particle Detection | Difficult to separate / Many false detections | High-precision separation |

| Setup Effort | Manual adjustment per image required | Automatic optimization |

| Result Consistency | Depends on operator and conditions | Stable results |

| Accuracy | Varies greatly by conditions | High accuracy |

| Ease of Use | Requires specialized knowledge | One-click analysis |